Drive Performance: Updating Your Building Machinery with Premium Komatsu Undercarriage Parts

Drive Performance: Updating Your Building Machinery with Premium Komatsu Undercarriage Parts

Blog Article

Reliable Solutions: Undercarriage Parts for Heavy Machinery

Quality undercarriage parts play a considerable duty in guaranteeing the smooth procedure and durability of hefty machinery. In this discussion, we will discover the importance of investing in excellent undercarriage parts, typical wear difficulties encountered by hefty machinery operators, the advantages of prompt substitutes, guidelines for selecting reputable distributors, and vital upkeep pointers to expand the lifespan of undercarriage components.

Significance of Top Quality Undercarriage Components

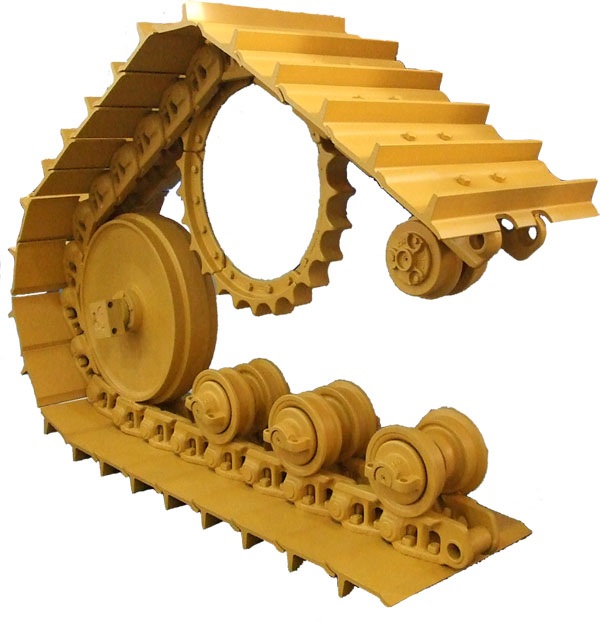

Quality undercarriage components are crucial components in guaranteeing the toughness and performance of heavy equipment. The undercarriage of equipment such as excavators, excavators, and track loaders plays a crucial role in supporting the equipment's weight, giving security on numerous surfaces, and soaking up the impact of uneven surfaces. By purchasing top quality undercarriage parts, operators can considerably prolong the lifespan of their machinery and reduce the threat of unanticipated failures.

One trick advantage of utilizing quality undercarriage parts is the improvement of total equipment efficiency. Long lasting tracks, gears, rollers, and idlers decrease friction and make certain smoother motion, eventually leading to increased performance and performance on task sites. Trustworthy undercarriage elements decrease downtime for upkeep and repairs, permitting operators to optimize their operational hours and task deadlines.

Typical Undercarriage Wear Problems

Benefits of Timely Substitute

One trick advantage of prompt undercarriage component substitute is boosted device uptime. By replacing worn components prior to they fail, the risk of unexpected failures is decreased, lowering downtime for fixings and upkeep. This positive method not just maintains the hefty machinery functional however likewise prevents possible damages to other parts that can result from a failing undercarriage.

Moreover, replacing undercarriage components quickly can enhance overall efficiency. Spending in timely undercarriage component substitute is a proactive method that pays off in terms of boosted effectiveness and lowered operational expenses.

Picking the Right Undercarriage Provider

Picking the appropriate undercarriage vendor is a vital choice that considerably affects the efficiency and maintenance of hefty equipment. When picking a supplier for undercarriage parts, numerous factors need to be thought about to make certain ideal efficiency and cost-effectiveness. It is important to examine the provider's online reputation and experience in the market. A trusted distributor with years of experience is most likely to offer high-grade parts and trustworthy solution. In addition, take into consideration the variety of products offered by the provider. A distributor that supplies a vast option of undercarriage parts for various hefty machinery brands and designs can be helpful as it supplies a lot more alternatives to meet specific needs.

Stabilizing Read More Here top quality, integrity, and cost-effectiveness is vital when picking the appropriate undercarriage distributor for hefty equipment. By meticulously examining these aspects, you can select a vendor that satisfies your demands and contributes to the efficient performance and upkeep of your hefty equipment.

Upkeep Tips for Extended Life Expectancy

To make certain an extended click to read life expectancy for hefty machinery undercarriage parts, executing an aggressive maintenance routine is vital. Spending in quality undercarriage parts from respectable distributors is equally crucial for making certain durability. By following these maintenance pointers carefully, hefty equipment proprietors can maximize the efficiency and durability of their undercarriage parts, ultimately reducing downtime and operational costs.

Verdict

To conclude, top quality undercarriage components are essential for the efficient procedure of hefty equipment. Timely replacement of worn components can protect against pricey downtime and keep optimum efficiency. Selecting a trustworthy vendor and complying with proper upkeep techniques are vital to making sure the prolonged lifespan of undercarriage components. By resolving typical wear issues and purchasing high-grade components, heavy equipment drivers can make best use of performance and reduce maintenance prices.

Excessive wear and tear on undercarriage components of hefty machinery can lead to considerable operational challenges and raised upkeep prices. Routine evaluations, proper upkeep, and prompt replacements of worn undercarriage components are crucial to minimize these typical wear issues and ensure the optimum performance of heavy equipment.

A vendor that supplies a vast option of undercarriage components for various hefty equipment brands and versions can be useful as it supplies much more choices More Help to satisfy specific demands.

By complying with these maintenance suggestions diligently, hefty machinery owners can enhance the performance and durability of their undercarriage components, inevitably minimizing downtime and operational expenses.

Report this page